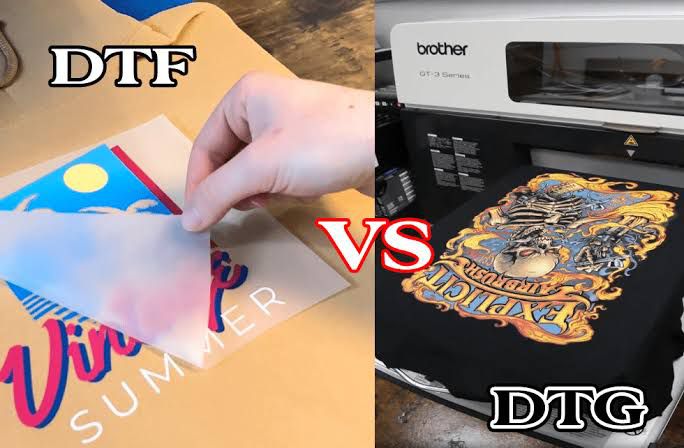

DTF (Direct-to-Film) vs DTG (Direct-to-Garment) Printing: Key Differences

When it comes to garment printing, **DTF** (Direct-to-Film) and **DTG** (Direct-to-Garment) are two popular technologies used for transferring designs onto fabric. While both methods allow for high-quality, full-color prints, there are significant differences in how they work, their advantages, and the types of projects they are best suited for. Let’s explore the key differences between **DTF** and **DTG** printing.

### 1. **Printing Process**

**DTF Printing**:

– First, in this process of printing through DTF, designs get printed on some special PET films with the aid of a highly specialized printer. Water-based ink is basically used for print. At this point once the design prints, powdered adhesives attach to the ink print when they’re still wet, and the heating film will be dried so that after that, one can easily attach it to fabric. Finally, the design is transferred from the film onto the garment using a heat press.

– **DTG Printing**:

– **DTG** printing works by directly printing designs onto the fabric itself using specialized inkjet printers. The ink is applied directly to the garment, where it soaks into the fabric fibers. A pre-treatment solution is often used for darker fabrics to ensure better ink adhesion and vibrant colors. After printing, the design is heat-cured to make it permanent.

### 2. **Ideal Fabric Types**

– **DTF Printing**:

– DTF can work well on fabrics from cotton and polyester to blend types, including even the hardness like leather and canvas. These reasons make this versatile in most areas when considering multiple fabric kinds or colors used for the textile work.

– DTF PRINT:

– **DTG** best works on cotton or cotton-blend fabrics. Although advanced DTG printers are able to print on polyester and other materials, the color vibrancy and durability of prints done on cotton fabric are far superior. It is less versatile compared to DTF in the use of a range of materials that it can be used on.

### 3. **Durability of the Print

– **DTF Printing:**

– The prints made with **DTF** are very durable and do not crack or fade easily. The adhesive in the transfer process helps the design bond strongly to the fabric, making the print long-lasting. It also maintains its vibrancy after several washes.

– **DTG Printing**:

– **DTG** prints are also long-lasting, but they may fade or crack easily if washed too many times. The durability of DTG prints depends on the type of fabric and the quality of pre-treatment and post-treatment processes.

4. **Print Quality and Detail**

– **DTF Printing**:

– DTF can yield very detailed prints with high color saturation; however, it cannot be as fine detailed as DTG. It excels in producing intricate designs and multi-coloured prints, especially on light and dark garments. However, because the design is transferred onto the garment, the feel may be a little thicker than DTG.

– DTG Printing

– **DTG** printing is a technique that uses photorealistic images and photo details, which are highly possible with this type of printing. The print is also softer and looks more natural since it absorbs directly into the fabric. DTG provides high-quality prints, particularly on light-colored garments with smooth gradients and fine finishes.

### 5. **Cost and Setup**

– **DTF Printing**:

– **DTF** printing is relatively cheaper for small businesses or those that require low to medium-volume runs. Although the initial investment in a **DTF** printer and equipment is expensive, the flexibility to print on various materials with minimal setup time makes it economical for custom orders or bulk runs.

– **DTG Printing**:

– **DTG** printers are also more expensive to purchase as an initial cost, especially when you need a printer that will print on several types of fabric. Although **DTG** printing is less expensive for short runs and individual pieces (due to no set-up costs for each design), it is more expensive for a large run compared to traditional screen printing.

6. **Speed of Production**

– **DTF Printing**:

– **DTF** printing prints faster than **DTG** based on production speed when orders are involved, especially with larger volumes. DTF enables the design to be first printed on a film and then directly transferred onto garments in large volumes, hence quick turnaround times with bulk orders.

– **DTG Printing**:

– **DTG** printing is slower than **DTF** printing, especially on individual garments. The direct printing process takes time, and each design may take longer to print compared to mass transfers like in DTF.

### 7. **Environmental Considerations**

– **DTF Printing**:

– **DTF** printing is more environmentally friendly than some traditional methods, mainly because it uses water-based inks and less setup. The transfer process might create extra plastic waste from the PET films used in the printing process.

– **DTG Printing**:

– **DTG** is also relatively eco-friendly compared to other printing methods, especially since it uses water-based inks that are less harmful than plastisol inks used in screen printing. Moreover, DTG reduces waste by enabling print-on-demand, eliminating the need for excess inventory.

### 8. **Applications and Best Uses**

– **DTF Printing**:

– Most suitable for producing prints on various materials. These are commonly used for transfer printing, promotional products, sports equipment, and apparel. DTG is a preferred method in cases of printing dark colors, mass production of garment products with complex designs, or the creation of customized products.

– **DTG Printing**:

It is best used for producing high-quality, detailed, and full-color prints on cotton or cotton-blend garments, especially in smaller runs, custom orders, or items requiring fine photographic or detailed designs.

### Conclusion

Both of these, **DTF** and **DTG**, have unique advantages that position them for various printing needs. **DTF** is good for versatility, order in bulk, and printing on almost any kind of fabric, whereas **DTG** does well regarding high-quality prints detailed with high resolution, especially on cotton.

Your choice between DTF and DTG depends upon your specific needs, such as the type of fabric, how complex the design is, and the speed with which you’re looking to make your production as well as a budget. Whatever business you operate in, including custom apparel businesses, limited edition fashion designs, or personalized items, both the technologies are powerful for consideration in this landscape of printing garments today.

What is DTG Printing?

DTG (Direct-to-Garment) printing is one of the newer forms of modern printing technology which lets designs get directly printed on to fabric by special inkjet printers. In the process, a liquid-based water-soluble ink gets placed on to the fabric very accurately, allowing highly detailed prints that are so vivid. Since it soaks in the fibers, the ink would actually be able to print such complicated designs and even photorealistic images as well as color gradients.

Unlike most traditional screen printing and heat transfers, DTG printing works much like a standard inkjet printer, but with the difference that the design is applied directly to the fabric rather than printing on paper. With this process, one can easily print very intricate designs or even custom ones, which might take time or even be almost impossible to produce by other methods.

### How Does DTG Printing Work?

The DTG printing process can be divided into the following steps:

1. **Design Creation**: A digital design is created on graphic design software like Adobe Illustrator or Photoshop. This can include anything from logos and illustrations to full-color artwork.

2. **Pre-Treatment**: For certain fabrics, especially dark-colored ones, a pre-treatment solution is applied to the garment. This treatment helps the ink adhere better to the fabric and ensures vibrant, long-lasting prints.

3. **Printing**: The T-shirt is placed inside the DTG printer, and the image will be printed right onto the textile. This printing machine utilizes proprietary water-based inks, which are absorbed into the fabric fibers.

4. **Curing**: Once the design is printed on the garment, the shirt goes into the curing cycle, which ensures that the ink dries under the application of heat, hence creating a permanent imprint and making the image resistant to fading and cracking over time.

5. **Final Product**: The printed apparel is ready to be sold or delivered, soft, and smooth with a very good print that does not flake off, with a feel that is nice and soft, too.

### Benefits of DTG Printing

There are several benefits to DTG printing that give it an edge over traditional methods of printing. Here’s why it has changed the game for custom apparel:

#### 1. **High-Quality, Detailed Prints**

One of the greatest benefits of DTG printing is that it can produce intricate, full-color designs with fine details and smooth gradients. This technology uses precision inkjet technology, meaning there is no loss of detail in complex artwork. Whether you’re printing a logo, a photograph, or a detailed illustration, DTG provides excellent print quality that rivals the original design.

#### 2. **No Minimum Order Requirements**

DTG printing is perfect for small runs, one-off items, and on-demand printing. Unlike screen printing, which requires costly setup and large minimum orders to justify the expense, DTG printing is ideal for businesses, designers, or creators who want to print a small quantity of garments with custom designs without the hassle or expense of large production batches.

#### 3. **Full-Color Printing Without Set-Up Costs**

DTG printers can print full-color designs directly onto fabric without color separation or making screens. It eliminates the costs of setting up and labor for traditional printing, which makes it especially useful for designs with multiple colors or complicated artwork. It also does not have limitations on color transition, which is challenging in traditional methods.

#### 4. **No Limitation on Design Complexity**

DTG printing does not have the same limitations as other printing methods like screen printing, where each color in the design requires a separate screen. With DTG, you can print any number of colors in a single pass, making it easier to execute complex designs and even photorealistic images with ease. Whether your design includes hundreds of colors or intricate patterns, DTG can handle it effortlessly.

#### 5. **Soft and Comfortable Feel**

Since the ink absorbs into the fabric fibers rather than resting on top of it (like heat transfer), prints from DTG printing are soft and light. This translates to a very comfortable garment, free from stiffness or bulkiness, even after several washes. This means, for the customers, a print that looks good and feels great against the skin.

#### 6. **Eco-Friendly Option

The use of water-based ink is the normal case in DTG printing since it is environment-friendly compared to plastisol, which is generally used in regular screen printing. Water-based inks do not contain any bad chemicals and therefore generate less waste, which might be more advisable for brands considering the environment for their clothing ventures. Also, since DTG printing allows the on-demand process of printing, one can reduce some overproduction waste and extra goods.

### End

It’s now shaping the clothing industry, particularly in the world of custom apparel, fashion start-ups and small-run production. That’s how DTG is changing the game:

#### 1. **Personalization and Customization**

This is because the advent of e-commerce and the print-on-demand service has made it possible to have more customized and personalized products. Businesses that make great money through the sale of personalized apparel like custom T-shirts and hoodies, as well as accessories, can access DTG to set up unique designs specific to the preferences of individual customers. This could, for example, be the name of a customer or a special graphic or even a one-off artwork.

#### 2. **On-Demand Printing and Reduced Inventory**

It makes on-demand production absolutely perfect since a business is not required to place huge orders for stocks or maintain unsold stocks in the stores. In DTG, it only prints on the garment at the time of the order; it minimizes the generation of wastes and provides for flexibility and agility in the business. This kind of on-demand capacity is a real advantage to small businesses or even entrepreneurs when trying out a new design and will not take risks in placing big orders for it.

#### 3. **Fashion and Designer Collaborations**

DTG printing allows fashion designers to make designs much more intricate and detailed without difficulty. It has become popular for limited-edition collections, collaborations, and boutique fashion lines where exclusive, custom prints are essential to the brand’s identity. Whether making a small run of luxury items or a custom-designed collection, DTG gives designers the freedom to experiment and push the boundaries of their creativity.

4. **Sustainability and Ethical Practices**

As consumers become increasingly conscious of sustainability, the fact that DTG printing is relatively eco-friendly makes it a much more attractive option for brands prioritizing ethical production methods. The use of water-based inks, minimal waste generation, and ability to print on demand make DTG a far more sustainable choice than traditional methods, especially given the market is increasingly moving toward environmentally responsible practices.

### Future of DTG Printing

As the technology of DTG printing develops, we will see further advancements in speed, quality, and efficiency. New models of printers are faster, cheaper, and can print on a wider variety of fabrics. This means that we will be seeing even more extensive use of DTG in different sectors of the apparel industry, from small startups to large brands.

### Conclusion

The apparel industry is indeed being transformed into a more excellent, customized, and environmentally-friendly print platform because of Direct-to-Garment (DTG) printing-a very innovative, powerful technology that’s taking this industry by storm. With complex design printing capabilities and full-color without setup costs and soft, long-lasting prints, DTG becomes the most-sought solution in businesses of every size. Whether you are a designer, a small business owner, or an enthusiast of fashion, DTG printing gives you the tools you need to bring your creative ideas to life with precision, speed, and sustainability.

As the apparel market continues to embrace customization, on-demand production, and environmental consciousness, DTG printing is poised to play an even bigger role in the future of fashion.

### What is DTF Printing?

**Direct-to-Film (DTF) printing** is a relatively new method of printing garments. It is a process of printing designs directly onto a special film, which is then transferred onto fabric. Unlike traditional methods such as screen printing or heat transfer vinyl (HTV), DTF allows for more intricate designs and vibrant colors to be applied quickly and efficiently.

The DTF process involves several key steps:

1. **Design Creation**: A digital design is created using graphic design software.

2. **Printing on Film**: The design is printed onto a special PET film (polyethylene terephthalate) using a specialized DTF printer. The ink used is typically water-based and highly pigmented.

3. Powder Adhesion. Once printed, a special adhesive powder is applied to the design while the ink is still wet. This powder is then heated to make sure it adheres to the design.

4. Heat Transfer. The film with the printed design is applied to the garment, and heat is used to transfer the design from the film to the garment.

This is high-quality, long-lasting, and durable print which is bright, and it can be applied on different kinds of fabrics like cotton, polyester, and blend.

### How DTF Works and its Advantages

Having gone through the basic concepts of DTF, let’s proceed with the discussion of why DTF has gained immense popularity in the clothing industry.

#### 1. **Vibrant and Detailed Prints**

One of the most impressive characteristics of DTF printing is the ability to replicate highly detailed and vibrant designs. Whether it’s complex graphics, intricate patterns, or photorealistic images, DTF delivers top-notch print quality with rich colors and fine details. Unlike other traditional methods, DTF doesn’t require using screens or stencils; hence, printing fine lines and gradients is done easily.

#### 2. **Versatility with Fabrics

DTF printing is also versatile in terms of the type of fabrics that can be applied. Unlike screen printing, which is often limited to a specific type of textile, DTF can be used on a wide range of materials such as cotton, polyester, blends, nylon, and even leather or canvas. This makes it an ideal choice for custom apparel, accessories, and promotional items.

#### 3. **Cost-Effective for Small Batches and Customization

DTF printing is effective for small-run or custom orders because a method like screen printing would be expensive for setting up every design. Nothing needs to be spent on expensive screens or molds since DTF is a digital print type. This makes it easy to change designs when necessary because of the digital nature of the print. Thus, DTF is perfect for businesses looking to make custom apparel without breaking the bank, particularly for a small batch or on-demand printing.

#### 4. **Soft Feel and Durability**

The soft feel of DTF prints is one of the major advantages over other heat transfer methods. Unlike screen printing, where the ink can sit on top of the fabric, DTF prints blend into the fibers of the material, resulting in a smoother, softer finish. DTF prints are also very durable. They do not crack or fade easily, even after multiple washes, making them a great choice for creating long-lasting designs on clothing.

#### 5. **Quick Turnaround Time**

DTF printing offers a faster production turnaround compared to some traditional printing methods. Since it’s a digital process, there’s minimal setup time required, and multiple designs can be printed simultaneously. This is a huge advantage for businesses that need quick delivery times for custom orders or limited-edition apparel.

### DTF in the Clothing Industry: How it’s Revolutionizing Fashion and Apparel

DTF printing has changed the face of clothing production and customization, due to its versatility, affordability, and quality. Here is a look at how DTF is playing a key role in the clothing industry:

#### 1. **Custom Apparel for Small Businesses and Startups

DTF printing opens the floodgate for small enterprises and entrepreneurs that can afford them to print high-quality bespoke apparel with negligible upfront costs. Whether a brand of clothing, looking for custom designs for some of their articles, or the business offers some personalized merchandise items, DTF makes it very easy and economic to print such products in fewer quantities. And with one-offs, there would be more than enough reason for niche markets and custom requests.

2. **On-demand Printing and E-commerce

With e-commerce and print-on-demand services emerging, DTF printing is more popularly being used by online stores and businesses dealing in personalized clothing. With no minimum order requirement and large productions runs, DTF printing helps businesses print designs on demand, thereby minimizing the need for holding massive inventory and minimizing waste. Customer order of customized designs; after a couple of days, the designs are printed and shipped to the customer.

3. Fashion and designer collaborations

DTF printing can be used on a number of fashion pieces, such as limited-edition collections and collaborations from famous fashion designers and apparel brands. This fast and affordable creation of high-quality, intricate designs makes it easier for designers to try out new concepts and add bold, creative graphics to their collections. The fashion world has always been known for its dynamic versatility in graphic tees, streetwear, athleisure, and many more with the help of DTF printing.

#### 4. **Eco-Friendly Printing**

Since DTF printing employs water-based inks and produces very little waste in terms of setup, it can be regarded as a greener option than screen printing, which requires toxic chemicals and massive amounts of water for cleaning. The direct-to-film process of DTF also reduces the use of physical screens or stencils, which can be expensive and wasteful.

Conclusion

DTF (Direct-to-Film) printing is moving fast through the clothing industry, creating versatile, cost-effective, high-quality printing. Something from bright and detailed prints to customization and reducing waste, it plays a great role in fulfilling the requirements of the modern fashion world. Whether one is a small business operator, an e-commerce retailer, or a fashion designer, DTF provides an innovative outlet to produce superior quality garments with comfort and ease.

The continued advancements in technology make DTF printing even more inevitable as an essential component of the fashion and apparel industry, providing easy means for making unique clothing items that meet customers’ demands.

### What is GSM? A Simple Definition

GSM stands for **Grams per Square Meter**, which is a measurement of weight or density. It is how much fabric is actually contained within a square meter of material. A simple word, GSM helps determine how thick, dense, or light a fabric is. Its texture, durability, and usability depend on it.

### Importance of GSM in Clothing Industry

GSM is an essential parameter in the clothes industry for quality and suitability of a fabric for various products. This is why it matters. It establishes why:

1. Fabric thickness and feel:

– GSM refers to the thickness of the weave; the thicker the weave, the heavier the fabric; the thinner the weave, the lighter the fabric. Less substantial and less luxurious fabrics are thus at lower GSMs, while those preferred for warm-weather clothes and layering would be at lower GSMs.

2. **Durability:**

– The higher the GSM, the more durable and long-lasting the fabric is because it has more material in its structure. For instance, heavier GSM fabrics like denim or canvas are known for their strength and resistance to wear and tear, while lighter GSM fabrics like cotton voile or muslin may not withstand harsh use as well.

3. **Breathability and Comfort**:

– The GSM of a fabric can also influence its breathability. Lighter GSM fabrics, such as those with a GSM of 100-150, are often preferred for summer clothing like T-shirts or blouses because they allow air to flow through, keeping the wearer cool. Heavier GSM fabrics, like those in towels or sweatshirts, provide more insulation and warmth, making them ideal for colder weather.

4. **Purpose of the Garment**:

– Various types of clothing need different GSM ratings. For example:

– **T-shirts**: A normal T-shirt would have a GSM between 140-200. The lighter GSM T-shirts are soft and perfect for hot weather, while heavier GSM T-shirts provide a more structured fit and can be used for colder months.

– **Towels**: Towels are usually more absorbent and plush due to their higher GSM, which ranges from 350 to 700 GSM.

– **Sweatshirts and Hoodies**: These have a GSM of 280-350, making them warm and comfortable during the colder seasons.

5. **Quality Indicator**

– GSM can also serve as a determinant of the quality of fabric. For instance, premium cotton fabric might have a higher GSM that would make it feel more luxurious and thick. Lower GSM fabric, on the other hand, may be less expensive but may be flimsier or less durable.

### GSM and Fabric Types

GSMs can vary in different fabrics based on the type of material used and the intended use. Some examples include:

– **Cotton**: The fabrics may vary between lightweight and fluffy, with an average GSM around 100, used for summer dresses to heavy and dense, about 500 GSM for towels or thick bedding.

– **Polyester**: Polyester’s average GSM tends to range from 100 to 300 in most clothing items such as shirts, sportswear, and outerwear.

– **Denim**: Denim fabric is typically a bit higher in GSM, at around 200-400 GSM, which explains why it is more durable and robust.

### Determining GSM

GSM is usually measured in a lab by specialized equipment. But you can do a quick check at home. Here’s how:

1. Cut a piece of fabric approximately 10 cm x 10 cm in size.

2. Measure the weight of the fabric on a sensitive scale.

3. Apply the formula to calculate GSM:

**GSM = (Weight of Fabric in grams / Area of Fabric in square meters) x 1000**

This is a very rough estimate and is usually used for small-scale measurements, such as checking fabric samples.

### The Bottom Line: Why You Should Care About GSM

Understanding GSM is important while shopping for clothing and fabrics because it lets you decide on your clothing needs about fabric quality, comfort, and durability. If you seek a soft, breathing T-shirt for summer or a cozy, heavyweight towel, knowing the GSM of a fabric will allow you to choose the right product according to your needs.

Ultimately, GSM is a key indicator of fabric characteristics, making it an essential part of both production and consumer decision-making in the clothing industry. Next time you come across GSM listed on a product label, you will have a deeper understanding of what that number means and how it influences the feel and performance of the garment!